PCD & PCBN Turning Tools

|

PCD & PCBN: Have higher hardness & abrasion resistance than other cutting tools. The advantages of these features are: Improving tool’s life, providing better control over part size and surface finishes, reducing tool cost per machined part, and improving machine productivity. Application: Polycrystalline Diamond (PCD): For machining non ferrous materials, carbon, ceramic, fiberglass composites, plastic and rubber Polycrystalline Cubic Boron Nitride (PCBN): For machining hardened ferrous material tool steel, alloy steel and cast iron |

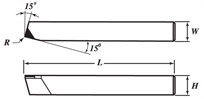

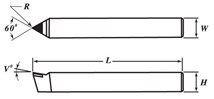

| Specifications. | Model No. | Tip Material | W | H | L | R | V° | S |

31 |

PB-4612-4G | PCBN | 16 | 16 | 120 | 0.4 | 0 | 0 |

| PB-4613-4G | PCBN | 19 | 19 | 140 | 0.4 | 0 | 0 | |

33 |

PD-6732-5A | PCD | 16 | 16 | 120 | 0.5 | 0 | 0 |

| PD-6733-5A | PCD | 19 | 19 | 140 | 0.5 | 0 | 0 | |

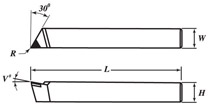

| PD-6530-3F | PCD | 10 | 10 | 80 | 0.3 | 10 | 0 | |

| PD-6531-3F | PCD | 13 | 13 | 100 | 0.3 | 10 | 0 | |

| PD-6532-3F | PCD | 16 | 16 | 120 | 0.3 | 10 | 0 | |

| PB-6630-4G | PCBN | 10 | 10 | 80 | 0.4 | 0 | 0 | |

| PB-6631-4G | PCBN | 13 | 13 | 100 | 0.4 | 0 | 0 | |

| PB-6632-4G | PCBN | 16 | 16 | 120 | 0.4 | 0 | 0 | |

34 |

PD-6540-3F | PCD | 10 | 10 | 80 | 0.3 | 10 | 0 |

| PD-6541-3F | PCD | 13 | 13 | 100 | 0.3 | 10 | 0 | |

| PD-6542-3F | PCD | 16 | 16 | 120 | 0.3 | 10 | 0 | |

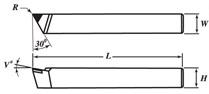

35 |

PD-6752-5A | PCD | 16 | 16 | 120 | 0.5 | 0 | 0 |

| PD-6753-5A | PCD | 19 | 19 | 140 | 0.5 | 0 | 0 | |

| PD-6550-3F | PCD | 10 | 10 | 80 | 0.3 | 10 | 0 | |

| PD-6551-3F | PCD | 13 | 13 | 100 | 0.3 | 10 | 0 | |

| PD-6552-3F | PCD | 16 | 16 | 120 | 0.3 | 10 | 0 | |

| PB-6650-4G | PCBN | 10 | 10 | 80 | 0.4 | 0 | 0 | |

| PB-6651-4G | PCBN | 13 | 13 | 100 | 0.4 | 0 | 0 | |

| PB-6652-4G | PCBN | 16 | 16 | 120 | 0.4 | 0 | 0 | |

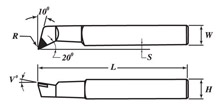

37 |

PD-6772-5A | PCD | 16 | 16 | 120 | 0.5 | 0 | 2 |

| PD-6773-5A | PCD | 19 | 19 | 140 | 0.5 | 0 | 2 | |

| PD-6571-3F | PCD | 13 | 13 | 100 | 0.3 | 10 | 2 | |

| PD-6572-3F | PCD | 16 | 16 | 120 | 0.3 | 10 | 2 | |

| PB-6672-4G | PCBN | 16 | 16 | 120 | 0.4 | 0 | 2 | |

| PB-6673-4G | PCBN | 19 | 19 | 140 | 0.4 | 0 | 2 |